B3500 Convection Reflow Oven

5-Zone Lead-Free Convection Reflow System with Combination Edge-Pin/Mesh-Belt

Conveyor and Windows-Based OS!

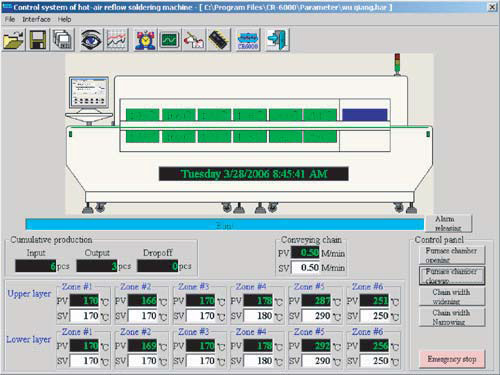

Part of our popular B-Series of premium-quality, small-footprint reflow systems, the B3500

includes 5 full zones of hot-air convection heating, each with independent upper and lower

temperature controls, a combination adjustable edge-pin/stainless steel mesh belt conveyor,

three thermocouple inputs, and a computer controller with a user-friendly Windows-based

operating system for precision temperature profiling.

◎ Affordably-priced, 5-zone "lead-free" model suits a full range of production requirements

◎ High-mass heat sources and efficient flow design allow full, forced convection reflow in a footprint 20%-30% shorter than comparable systems

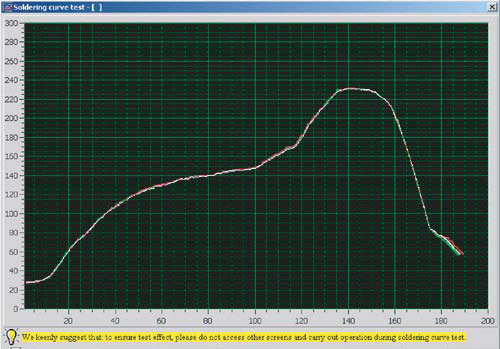

◎ Independent upper and lower PID temperature controls for each heat zone and three thermocouple inputs for accurate "lead-free" temperature profiling

◎ Combination stainless steel mesh belt and adjustable edge-pin-type conveyor handles

◎ PCBs up to 450 mm wide; 550 mm on mesh belt

◎ Easy-to-use Windows-based user interface with advanced temperature profiling and thermal management functions

◎ Timed automatic startup and shutdown modes for power management and energy

◎ conservation

◎ Includes industrial PC, LCD flat-screen monitor

◎ UPS battery backup to ensure product protection in the event of power outage (Optional)

◎ CE certified

◎ Small footprint - only 3m length

General:

Tin Lead (SnPb) Compatible

Double-Sided Board Processing

CE Compliance

SMEMA Compatible (Optional)

Board Handling:

Heated Board Width: 570mm

Mesh Belt Conveyor (Standard)

Mesh Belt Width: 570mm

Chain-Driven Pin Conveyor (Standard)

Pin Conveyor Max. Width: 450mm

Pin Conveyor Min. Width: 50mm

Auto Adjust Pin Conveyor (Optional)

Powered Center Support (Optional)

Automatic Chain Lubrication

Conveyor Speed: 400-1800mm/min

Conveyor Height: 900mm ±20mm

Conveyor Direction: Left to Right

Component Max. Height: 30mm upper, 25mm lower

Heating:

Forced Hot Air Convection

Number of Independently Controlled : 10 total

Heating Zones: 5 upper, 5 lower

Total Heated Length: 1910 mm

Number of Oven Convection Motors: 10 / Power: 120W x 10

Delta T: ±2° C

Temperature Controls:

PID (Proportional-Integral-Differential)

Temperature Control Accuracy :±1° C

PCB Temperature Tolerance :±2° C

Temperature Range: Ambient -300° C

Ramping Time (from cold start): < 15 min

Profiling / Thermocouple Channels: 3

Cooling:

Standard Cooling Method: Air

Number of Cooling Zones: 1

Cooling Tunnel Length: 370 mm

Exit Temperature: 40°C

Number of Cooling Fans: Three 45W

Operating System and User interface:

Windows Compatible PC

On-Screen Thermal Profiling and Parameter Setting

Print Capability

Data Logging & Event Recording

Alarms :Audible, Visual (Light Tower) and On-Screen Display

Dimensions and Physical Characteristics:

Size: L3040 X W1380 X H1445 mm

Net Weight:1220 kg

Utilities:

Power Supply: 220 VAC 3-Phase

Frequency: 60Hz

Operating Power Consumption: 6.5-10 KW

Start-Up Power(Sequential Start-Up Mode*): 16 KW

Current(Sequential Start-Up Mode*): 70A

Total Power (Maximum): 38 KW

Number of Exhaust Vents: 2

Exhaust Opening Size: 8" x 2"

Total Exhaust Venting Volume: 260 CFM

*Sequential Start-Up Mode is the default start-up mode and

limits current draw during start-up.

Miscellaneous:

Hood Opening Mechanism: Automatic Raise and Lower

Related Products

SD301 Bench-top / Batch Reflow Oven

Dynamic Thermal Profile using a Batch Reflow Oven with Android™ Operating System

B3500 Convection Reflow Oven

5-Zone Lead-Free Convection Reflow System with Combination Edge-Pin/Mesh-Belt Conveyor and Windows-Based OS!Product Categories

Contact Details

- Sulzbacher Str. 111 92224 Amberg, Germany

- +49 (0) 9621-600 691

- +49 (0) 9621-600 692

- sales@soldertronic.com